Marine rope Marine Mooring/Towing Rope/Line, from diameter 4mm-120mm.

All Ropes will be testing before leaving factory to ensure the Tension Capacity;

What’s more, All Ropes will be packing with bag, easy to transport by forklift.

High strength, wear-resistant, durable, moldy and alkali resistant, simple and lightweight. Instructions for use: Every time the safety rope is using, a visual inspection must be carriying out.

During use, attention should also be paid to checking and testing should be conducting once within half a year to ensure that the main components are not damaging.

In addition to light weight, high strength, good impact resistance and wear resistance,

ship ropes have advantages such as corrosion resistance, mold resistance, and insect resistance.

If the strength and wear resistance of nylon cables exceed that of hemp and cotton cables several times,

and the specific gravity of polypropylene cables is less than that of water, they can float on the water surface, making operation convenient and safe.

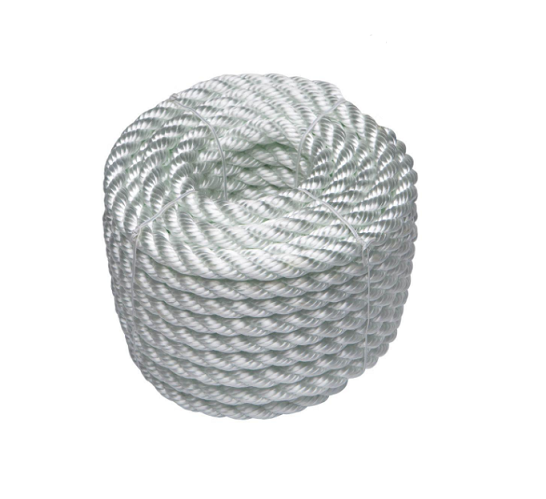

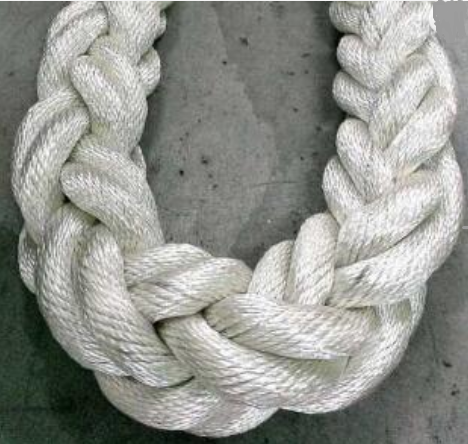

Chemical fiber ropes are divided into two types according to their processing structure:

3-strand, multi-strand twisted ropes, and 8-strand, multi-strand braided ropes.

The diameter of a 3-strand cable is generally 4-50 millimeters, while the diameter of an 8-strand cable is generally 35-120 millimeters.

The correct use of the cable not only improves the safety of the sailors and crew, but also extends the service life of the cable Before use,

the Chief Officer (bow) or Second Officer (position transmitter) carefully checks the integrity of the cable. If there is excessive wear or a large number of broken ends in a certain part of the cable,

replace the cable in a timely manner.

If there is no time to replace, try not to let this cable bear too much tension during use to prevent sudden breakage.