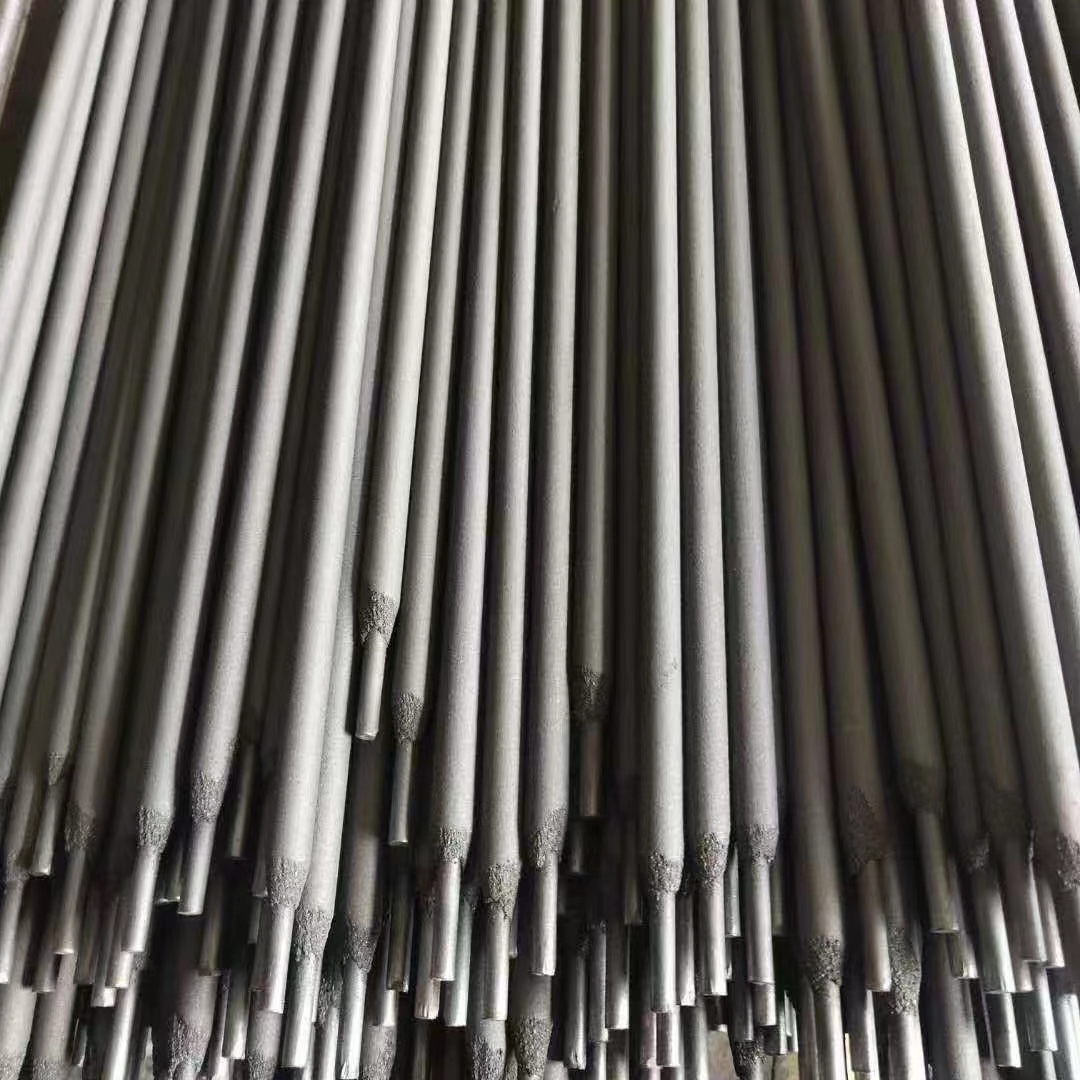

E6010 Welding Rod 3/32″ 1/8″ 3/16″ Welding rod, diameter customizing,

like 0.8mm, 2mm, 3.2mm, 4mm, with carton box packing for delivery

E6010 Welding Rod

Carbon steel welding rod

Explanation: E7018 is a carbon steel electrode with iron powder and low hydrogen potassium coating. Both AC and DC, capable of full position welding. Its characteristic is that the coating contains iron powder, which can reduce the number of welding layers.

Usage: Suitable for welding carbon steel and low alloy steel, such as 16Mn.

Chemical composition of deposited metal (%)

C Mn Si S P ≤0.12

≤1.60

≤0.75 ≤0.035 ≤0.040

Reference current

Welding rod diameter (mm) 2.5 3.2 4.0 5.0 Welding current (A) 90-120

120~150

170~200 210~250

While matters needing attention:

1. Before welding, the welding rod must be baking at around 350 ℃ for 1 hour and using as needed.

2. Before welding, impurities such as rust, oil stains, and moisture must be removing from the welded parts.

3. Short arc operation must be using during welding, preferably with narrow weld beads.

When using a DC power supply, connect the welding rod to the positive electrode.

E6010 is a DC high cellulose sodium coated electrode.

While This welding rod can be using for all position welding with high arc blowing force, achieving single sided welding and double sided forming.

It has fast melting speed, clear melting pool, easy slag removal, strong anti porosity performance, and convenient operation.

It can be applying to other welding fields with high requirements for all position welding technology, such as boilers, pressure vessels, large bridges, etc.

matters needing attention:

1. It is not allowing to re bake the welding rod before welding

2. This type of welding rod should be stored in a closed container.

While the packaging is opening, it should be using as soon as possible to avoid prolonged exposure to sunlight or environments with significant temperature changes.

3. When welding with 4.0mm welding rods, try to use high thrust and low current as much as possible to improve welding performance.