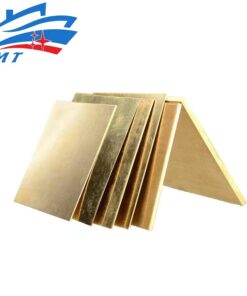

Marine Aluminum/Stainless Steel/Bronze rudder stock sleeve

In addition, rudder stock sleeve Bearings Carefully hand polishing by our workers to make it perfect.

What’s more, We can customize the sleeve, design according to the type&Weight of you

to help your vessel work perfectly!!!!

The rudder stock shaft sleeve forging is a shaft forging meticulously produced by our company,

which combines the advantages of domestic and foreign shaft forgings and is strictly customized according to customer requirements.

The rudder stock shaft sleeve blank has the characteristics of good continuity of metal fiber structure

excellent material quality, high productivity, and impact resistance.

It is a popular shaft forging product among customers,

with a wide range of applications, such as aerospace, forging machinery, machine tool manufacturing, accessories, etc.

It is one of the commonly used shaft forgings in mechanical manufacturing,

nuclear power equipment, locomotive manufacturing, and forging machinery,

Forgings that use impact or pressure to deform metal freely in all directions between the upper and lower anvil surfaces,

without any restrictions, to obtain the required shape and size, as well as certain mechanical properties

Rudder pin shaft sleeve blank forging processing, which can cut the metal blank into the required size, heat, forge, heat treat, clean, and inspect

The blank forging of the rudder pin shaft sleeve has refined grains, dense structure, as well as a continuous forging flow line,

improving the mechanical properties of the forging metal

Forging processing mainly involves heating the blank metal billet of the rudder pin shaft sleeve,

placing it between the upper and lower needle anvils of the forging equipment while applying impact force or pressure to cause plastic deformation

The rough forging of the rudder pin shaft sleeve has good toughness, reasonable fiber structure, while minimal performance changes between forgings